L1100 2-Post Car Lift Auto Truck Hoist 10,000 lb Overhead Clear Floor 220V

Auto Car Lift L1100 220V 60HZ 1PH 3HP MOTOR features Symmetrical Arm Assembly with Straight Front / Rear 2 Stage reach from 30 1/4″ to 49 1/5″ and Equal length of front and rear arm design Drop-in type lifting pads and truck adapters are included.

Features:

Safety Mechanism:

- Double Point Safety Lock Release

- Automatic arm lock restraints

- Relief valve built in power pump to prevent overloading

- Door guards protection rubber

- Up-limit switch to protect cylinders working stroke used in safe length scope

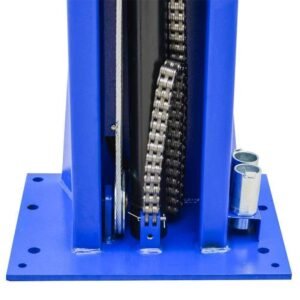

- Heavy duty 5/16″ diameter cable and 4.56″ pulley reduce high stress on synchronization process and increase cable life

- Stiffened base plate 5/8″ thickness

- Ultra high molecular self lubricating nylon slider ensures carriage smooth moving up and down

- Anchor bolts/mounting hardware included

Control System:

- Lifting operation by pressing “UP” button on motor

- Manual lowering operation by pressing lever

- Relief valve built in power pump to prevent overloading

- 1 sets truck adapters included

- Lifting Capacity: 10,000 lbs

- The overall Height 145-5/8″

- The overall Width 133-1/4″

- Column Width 10.62″

- Base Width 18.89″

- Column Thickness of Steel 3/16″

- Carriage Thickness of Steel 15/64″

- Arms Thickness of Steel 15/64″

- Front Arm 30.7″ to 48

- Rear Arm 30.7″ to 48″

- Min pad height: 3-7/8″

- Lift height max: 78-7/8″

- Drive-thru width clearance: 100″

- Time to full rise: 20-60 sec

- Shipping Weight: 1460 lbs

Site Selection:

Before installing your auto lift, check the following:

- Lift Location: Always use architect’s plans when available.

- Check layout dimension against floor plan requirements making sure adequate space is available.

- Your lift requires a 220v, 30amp, single phase, grounded electrical source. There should be room enough to operate the lift in a safe manner and without restrictions.

- Overhead Area: The area where the lift will be located should be free of overhead obstructions such as heaters, building supports, electrical lines, doors, lights, etc.

- Floor Area: Visually inspect the site where the lift is to be installed and check for cracked or defective concrete.

Floor Requirements:

- A level floor is suggested for proper installation and level lifting. Small differences in floor slopes may be compensated for by proper shimming. If a floor is of questionable slope, consider a survey of the site and/or the possibility of pouring a new level concrete slab.

- New concrete must be adequately cured for at least 30 days.

- DO NOT install auto lift on any asphalt surface or any surface other than concrete.

- DO NOT install auto lift on expansion seams or on cracked or defective concrete.

- DO NOT install auto lift on a second/elevated floor without first consulting building architect.

- DO NOT install auto lift outdoors unless special consideration has been made to protect the power unit from inclement weather conditions.

Concrete Specifications:

All models MUST be installed on 3,000 PSI reinforced concrete only. Additional concrete requirements will vary by lift.

- 8,500 lbs – 10,000 lbs lifts: 4″ Minimum Thickness

- 11,000 lbs – 15,000 lbs lifts: 6″ Minimum Thickness

specifications:

- Condition: New

- Modified Item: No

- Custom Bundle: No

- Material: Metal

- Capacity: 10000lbs.

- Type: 2-Post Lift

- Features: Hydraulic

- Vehicle Type: Passenger Vehicle

- Brand: ,XK USA

Reviews

There are no reviews yet.